Aging with Intention: Engineering the Maturation of Spirits - Part 6

The previous article discussed concentrating and purifying low ABV liquid into a spirit. This article will discuss the next step in the spirits production flow, maturation.

Technical Background

After distillation, the spirit can take several paths depending on the desired end product. Vodka is filtered to remove any color, aroma, or flavor and can then be bottled. Gin and blanco tequila also do not require maturation and can be bottled after distillation. Blanco tequila can be optionally aged for 2 months or less before bottling.

Whiskey, brandy, rum, and aged tequila all require maturation. Typically, this is done, and required for some spirits, in oak containers. Stainless steel can also be used to mature spirits. Maturation allows chemical reactions to take place within the container, which develops color, aroma, mouthfeel, and flavor. For further reading on the chemical interactions happening within the barrel during bourbon aging see (Demoranvill).

The chemical compounds developed either in fermentation or maturation are called congeners. The congeners add positive changes to the distillate but can also add to a hangover. In a study comparing drinking low congener (vodka) and high congener (bourbon) alcohol, the study found “beverage congeners in bourbon versus vodka did significantly increase the intensity of hangover that was felt, consistent with results from studies in the 1970’s” (Rohsenow).

During maturation, volume in a barrel might be measured in wine gallons or proof gallons. Wine gallons are the total volume in a barrel or other container independent of proof. Proof gallons refers to the equivalent volume of ethanol if it were converted to 50% (or 100 proof) ABV wine gallons.

Proof Gallons = Wine Gallons x (Proof / 100)

If a whiskey barrel is full of 50 gallons of 120 proof spirit, the contents could be referred to as 50 wine gallons, or 60 proof gallons.

How Matrix can help

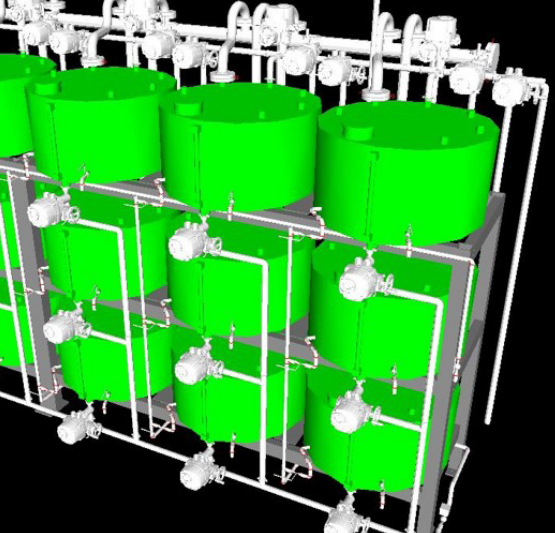

An example of a successful project within the maturation step, was a single barrel operation to improve safety and throughput time. Matrix designed the mechanical, electrical, and automation needed to disgorge a single barrel and transfer the contents to a small tote. Flow meters completed initial proofing with RO water between the barrel and tote. Once in the tote, the liquid could be further proofed and/or recirculated for chill filtering, before being routed to the appropriate filling line. The process was completely manual before this project and personnel were at risk of injury with barrels rolling around continuously.

The climate for oak barrel storage can affect the aging and quality of spirits, which can affect the bottom line and brand reputation of a distiller. Matrix Technologies can provide a wireless network of IIoT (Industrial Internet of Things) sensors to monitor the barrel warehouse climate for compliance and send alarms via email or text for out of tolerance conditions. The monitoring and data collection solution is a secure, wireless, low power, long range, and non-invasive answer to centralized monitoring of all warehouse climates that is quickly deployed and easily scaled.

Three-dimensional model of a design solution to improve safety and reliability of a single barrel disgorging operation.

The next and final article in the series will discuss bottling of the spirit.

References:

Demoranvill, Heist. “The Chemistry of Bourbon.” Chemical Engineering Progress August 2021: 40-45.

Rohsenow, et al. “Intoxication with Bourbon versus Vodka: Effects on Hangover, Sleep and Next-Day Neurocognitive Performance in Young Adults.” n.d.

© Matrix Technologies, Inc.